Centrifugal Force Test /

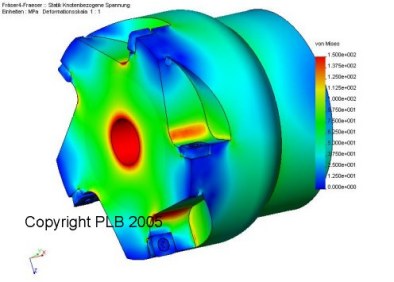

Spin Test / Burst Test and Finite Element Analysis

PLB Test Laboratory for Operating Strength GmbH

PLB GmbH Charlottenstr. 98 Tel. + 49 7121 490827

D-72764 Reutlingen

High Speed Spin Test of Rotating Parts

|

|

|

|

|

|

|

|

|

|

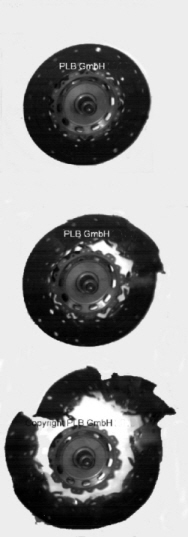

Highspeed Video of a burst test

Spin test stand

centrifugal force test stand (Schleuderprüfstand / Spin test stand)

up to 80 000 rpm to determine:

burst speed (Burst Testing)

beginning of deformation

radial growth of rotating parts and assemblies

factor of safety against fracture

factor of safety against deformation

Test Parts (Spin test, Burst test) Test Reports

Radial fan wheel

Axial flow fan wheel

Dual-mass Flywheel

Clutch lining, pressing plate

Torsion absorber

Wheel brush

Claw pole generator, Hybrid Motor, electric motor anchor

Milling cutter, cutter block, planer, shaper

the Centrifugal Force Type Test

according to the Standard EN 847-1 and EN ISO 15 641.

e-Mail: Info@PLB-GmbH.de

© Copyright 2005-2024 PLB GmbH. All rights reserved.